In the rapidly evolving landscape of technology, the concept of the Digital Twin stands out as a groundbreaking innovation. This technology, which bridges the gap between the physical and digital worlds, is transforming various industries by enhancing efficiency, reducing costs, and driving innovation. This article delves into what Digital Twins are, how they work, their applications across different sectors, and the future prospects of this technology.

What is a Digital Twin?

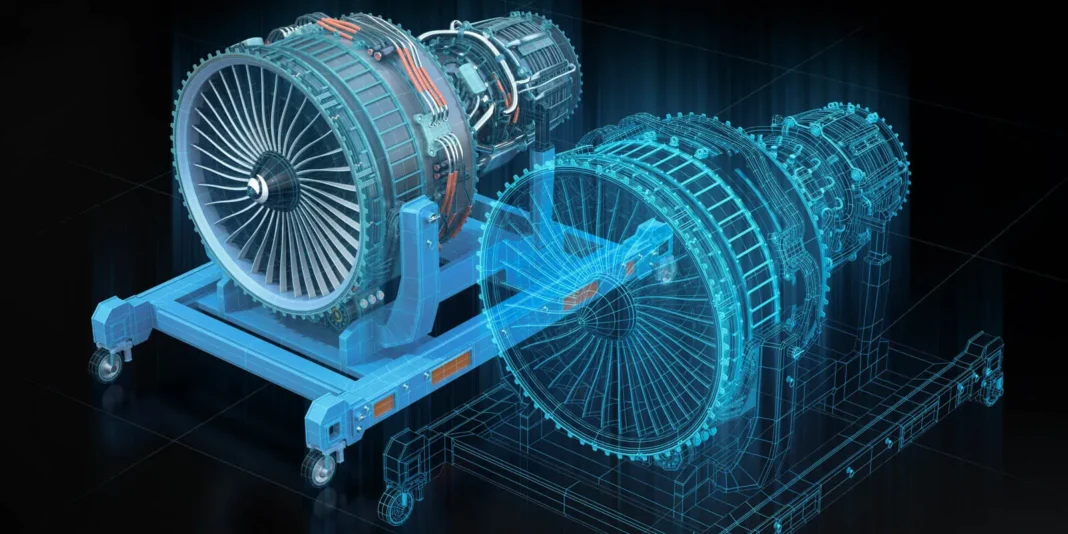

A Digital Twin is a virtual replica of a physical entity or system. This digital model simulates the behavior, characteristics, and interactions of its real-world counterpart using real-time data. By integrating IoT sensors, machine learning algorithms, and data analytics, Digital Twins provide a dynamic, real-time representation of physical assets, processes, or systems.

The concept, initially applied to physical objects, has expanded to cover processes, people, and even entire ecosystems. For instance, a Digital Twin of a city might include data on traffic flow, weather conditions, and public services to simulate and optimize urban management.

How Does a Digital Twin Work?

Digital Twins operate by creating a digital model that mirrors the physical entity it represents. The process involves several key steps:

- Data Collection: Sensors and IoT devices gather real-time data from the physical entity. This data includes environmental conditions, operational metrics, and other relevant information.

- Model Creation: Using the collected data, a detailed digital model is created. This model represents the physical entity’s structure, behavior, and interactions.

- Simulation and Analysis: The digital model is used to simulate various scenarios, analyze performance, and predict future outcomes. This simulation helps in understanding how changes to the physical entity might impact its performance.

- Feedback Loop: Insights gained from the digital model are fed back into the physical entity, enabling adjustments and improvements based on the simulated outcomes.

Applications of Digital Twins

The versatility of Digital Twins allows them to be applied across various industries. Here are some notable applications:

1. Manufacturing

In manufacturing, Digital Twins are used to optimize production processes, improve product design, and enhance maintenance strategies. By simulating production lines and machinery, manufacturers can identify bottlenecks, predict equipment failures, and implement preventive maintenance strategies. This results in increased efficiency, reduced downtime, and cost savings.

2. Healthcare

Digital Twins in healthcare can create personalized models of patients to simulate treatment outcomes and monitor health conditions. For example, a Digital Twin of a patient’s cardiovascular system can help in predicting the impact of different treatments and interventions. This personalized approach can lead to more effective treatments and improved patient outcomes.

3. Urban Planning

City planners and architects use Digital Twins to model urban environments, including infrastructure, traffic flow, and public services. This simulation helps in designing more efficient and sustainable cities. By analyzing different scenarios, planners can optimize traffic management, improve public transportation, and enhance overall urban living conditions.

4. Aerospace and Defense

In aerospace and defense, Digital Twins are used to simulate and test aircraft systems, spacecraft, and defense mechanisms. This technology helps in predicting the performance of complex systems under various conditions, leading to improved design, reliability, and safety.

5. Energy Sector

Digital Twins in the energy sector are utilized to monitor and manage energy production and distribution. By simulating energy grids, power plants, and renewable energy sources, operators can optimize energy distribution, predict equipment failures, and enhance the efficiency of energy systems.

Benefits of Digital Twins

The adoption of Digital Twins offers several benefits across industries:

- Improved Efficiency: By simulating and analyzing processes in real-time, organizations can identify inefficiencies and optimize operations.

- Cost Savings: Predictive maintenance and optimized processes lead to reduced operational costs and extended equipment lifespans.

- Enhanced Decision-Making: Data-driven insights from Digital Twins enable informed decision-making and strategic planning.

- Risk Reduction: Simulating various scenarios helps in understanding potential risks and developing mitigation strategies.

- Innovation and Development: Digital Twins facilitate rapid prototyping and testing, accelerating innovation and product development.

Challenges and Considerations

Despite its benefits, the implementation of Digital Twins comes with challenges:

- Data Security and Privacy: Handling sensitive data requires robust security measures to protect against breaches and ensure privacy.

- Integration and Compatibility: Integrating Digital Twins with existing systems and technologies can be complex and require significant effort.

- Cost of Implementation: The initial setup and maintenance of Digital Twins can be costly, particularly for small and medium-sized enterprises.

- Data Management: Managing and analyzing large volumes of data from Digital Twins requires advanced data management and analytics capabilities.

The Future of Digital Twins

The future of Digital Twins looks promising as advancements in technology continue to drive innovation. Emerging trends include:

- Enhanced AI Integration: Integrating artificial intelligence with Digital Twins will further enhance predictive capabilities and automation.

- Expansion to New Sectors: Digital Twins are expected to expand into new sectors, including agriculture, education, and retail.

- Increased Interoperability: Improved interoperability between different Digital Twin systems will facilitate more comprehensive simulations and analyses.

- Sustainability and Resilience: Digital Twins will play a crucial role in developing sustainable practices and resilient systems to address global challenges.

Conclusion

Digital Twins represent a transformative technology that bridges the gap between the physical and digital worlds. By leveraging real-time data, simulations, and predictive analytics, Digital Twins enhance efficiency, reduce costs, and drive innovation across various industries. As technology continues to evolve, the potential applications and benefits of Digital Twins are bound to expand, offering exciting opportunities for businesses and organizations worldwide.